The moment a supplier's trustworthiness has long been set up by validation of their check benefits, a maker could perform the Visible evaluation solely in the warehouse.

(3) Usage of visual inspection to carry out a 100-percent assessment for appropriate labeling in the course of or immediately after completion of finishing functions for hand-used labeling. This sort of evaluation shall be performed by 1 particular person and independently confirmed by a next individual.

The objective of FDA's PAT software should be to facilitate adoption of PAT. Within our 2004 steerage, we discuss FDA's collaborative method of promote business uptake of latest and effective systems that modernize manufacturing functions and greatly enhance procedure Manage.

Validated analytical solutions are needed for tests each and every batch, which includes validation batches. The Company would also expect the maker to make use of a validation protocol that features a review and remaining report immediately after several batches are done, even though the sooner batches may well are actually dispersed or used in the concluded drug merchandise.

Examine our guides to master ideal techniques on how to eliminate issues and dangers and launch high-high quality, compliant items to market.

Manufacturing processes should be managed, and any improvements to the procedure have to be evaluated. Modifications that have an effect on the quality of the drug are validated as vital.

(b) Any labeling or packaging resources meeting appropriate written technical specs may very well be approved and released to be used. Any labeling or packaging supplies that do not fulfill such specs shall be rejected to circumvent their use in functions for which They can be unsuitable.

indicates any component meant to be used during the manufacture of a drug products, together with These that may not seem in these kinds of drug product.

Oral Reliable Dosage From pellets, tablets and capsules to ground breaking launch profiles, We've got the worldwide knowledge to assist meet your preferences throughout a wide array of platforms and technologies.

Both of those GMP and cGMP manufacturing create substantial-top quality results. Each and every follows regulatory guidelines that make the safest, purest, and many high-high-quality products. However, with cGMP pharmaceuticals, the company has absent to the best lengths to ensure the security and good quality cgmp compliance with the solutions are meeting the mandatory requirements.

one µm pore dimension rated filters (see Faine 1982). Compendial microbiological take a look at strategies usually used in Affiliation with upstream biotechnology and pharmaceutical manufacturing will not be able to detecting such a microorganisms. No matter if this apparently uncommon contamination hazard might cgmp guidelines be far more common is unknown, and we're sharing this information in order that manufacturers can consider no matter if this hazard could be applicable to their operations.

That 11 issue record was just a number of policies, processes, techniques, or audits which the whole world Health and fitness Organization wants you to own documented, then to follow.

Our solutions APIs & Intermediates We operate intently along with you throughout the synthesis of one's API and biologic drug substance, employing operational excellence across our total course of action.

Small Molecule APIs We have a roster of analytical chemists, natural and organic chemists and engineers who are adept at developing and hassle-shooting analytical methods and processes and also have the abilities to assist scale up your API procedure.

Scott Baio Then & Now!

Scott Baio Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Destiny’s Child Then & Now!

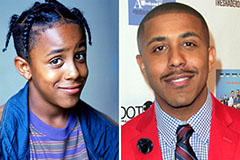

Destiny’s Child Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now!